|

|

The Judson Register is Closing/Relocating

2nd November 2015

|

After just over 15 years running this website on Judson Superchargers it’s time to make moves to secure the information for the foreseeable future. The main components of the website have been carefully dismantled into its useful component parts and re-housed for future generations of “Vintage Speed” enthusiasts. Where can you find these “useful component parts”? After a discussion with Everett Barnes of The Samba.com he has kindly found a cosy corner of The Samba Archive to house Judson History...Installation Instructions...Promotional Material... Magazine Test Reports and Technical Articles….the meat of this Judson Register website. You’ll find it all here: http://www.thesamba.com/vw/archives/lit/ If you have questions about your VW installation or fine tuning your Judson kit then The Samba.com also has an excellent “Vintage Speed” forum where you can pose your questions or search the forum to find many questions have already been answered: http://www.thesamba.com/vw/forum/viewforum.php?f=44 Just one last BIG vote of thanks to all the Judson enthusiast out there who helped make this website “the place to go to” for information relating to Judson Superchargers. I’d particularly like to thank the late W. Haddon Judson jnr. (Haddie) R.I.P, Rocco Antonelli, Alejandro Martin and George Folchi…without their assistance and knowledge, the understanding of Judson Superchargers and the people behind it, would be incomplete. If you need Judson parts, a restoration or a full kit you’ll find George Folchi, (gbfolchi@yahoo.com) Alejandro Martin (almar9@hotmail.com) and Richardo Deisernia (http://www.splitpartsunlimited.com/index.php) are still able to meet your needs. Thank you again...it's been fun. John E Moxon

|

|

Judson Research & Mfg. Co. History

|

|

Since 1880 the Judson Family have been involved in some form of mechanical and electrical engineering. It's a story of enterprise and innovation, from farming machinery through to electronics for the defence and automotive industries. Of course stationed along the route was the Judson Supercharger, a product that was a natural spin-off from a small interest in producing custom-made racing superchargers. |

|

|

|

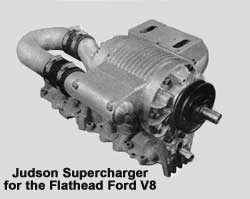

The

supercharger manufacturing unit was part of Judson Bros. of

Collegeville PA,- who made farming machinery- this

company was absorbed into what was to become the parent company, Judson

Research & Mfg. Co. of Conshohocken PA. in the early 1950s. Production

superchargers were developed shortly after this amalgamation, starting with a

sliding vane supercharger for the Flathead Ford V8, followed W. Haddon

Judson (1914-1988) was the prime mover in the development of the company and

in the technical innovation of the supercharger aided by his brother Charles A Judson. New

models were added steadily over the next five years until the full range

included superchargers for MG TD, TF and MGA, Renault Dauphine, Triumph TR3

and 4, Mercedes 190SL, Volvo, Austin-Healey Sprite, the Corvair

and of course two versions for Volkswagens. The two VW types were a natural

progression. The first was for the 30/36hp engine and the second for the

34/40hp unit introduced in August 1960. For the Karmann Ghia the kit included

an aluminium air scoop for the deck lid but in all other respects the two

Judsons fitted across the range until the advent of the 1500cc engine in

1967. From the outset it didn't take long for Volkswagen owners to look for ways to breathe new life into their underpowered Beetles. As a consequence business for the Judson Research & Mfg. Co. and in particular sales for their VW Judson Supercharger flourished. Despite the sliding vane supercharger's origins as a bespoke unit for motor sport, the Judson company wisely targeted the average motorist in its advertising campaigns. It's easy to understand, the mass market was the average guy. Certainly with the Volkswagen, which was an economy model, it was important not to price the supercharger kit out of their reach. |

|

Advertising. |

|

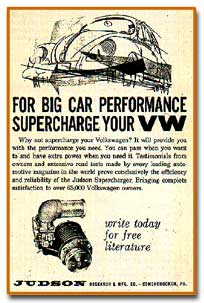

The

advertising firm that handled the Judson account was the "Williams

and Avery Advertising Co." in fact this was simply William

Haddon Judson and Charles Avery Judson...they kept everything "in

house." Early

advertising was strictly factual without fancy flourishes; pictures were

straight engine shots and text just emphasised the power gains that could be

got by fitting a Judson Supercharger. The adverts offered "Free

literature and data" by writing to the company in Conshohocken. From

1953 onwards "Road & Track" magazine was one of the main

advertising outlets with a more noticeable presence when the magazine

conducted a road test on the latest Judson model. Reviews of the Judson

models started in November 1953 when the Judson for the Flathead Ford was

reviewed in the magazine "Speed Age"

followed a year later with the "Road & Track"

review for the Judson MG-TF model. With the

introduction of the VW model in early 1956 the promotional material for

Judson Superchargers became more model specific, with the VW Judson getting a

brochure and a promotional postcard sent out to those responding to magazine

adverts. The VW Karmann Ghia, Volkswagen's new "sporting A new

addition to the newsstands at this time, afforded the Judson Company with

another avenue of exposure; the magazine "Foreign Car Guide" . In the

first issue of Fall 1956 the magazine ran an article outlining supercharger

options for the VW. The article, although mentioning most of the Judson's

small supercharger rivals, featured the Judson heavily in its text and with a

page of pictures giving pictorial instructions of the Judson installation. A

review of the VW model appeared in the September 1957 issue of "Road & Track";

the positive review also giving sales a useful boost. From the

VW model's early exposure in issue number one of "Foreign Car

Guide," the Judson Company took the back page of every issue of the

magazine until December 1966. It's in the company's back page advertising for

"Foreign Car Guide" that you'll notice a more "look at

me style" with a stylised graphic of a speeding Beetle, a space-age

rocket advertising 50% more power and how to turn your Beetle into a

"Super Beetle." In the "Foreign

Car Guide" the company had found the ideal billboard for its best selling supercharger as,

with the popularity of the VW Beetle, the magazine's content began to be

dominated by the German import. |

|

Sales |

|

Right

from the start of the VW model the company claimed in it's

advertising, "thousands of happy owners". Well yes, eventually they

did sell thousands of the VW model but those early claims, in the 1956

brochures were something of an exaggeration. At this

stage the company were offering their kits, direct from the factory, through

specialist agents and official VW dealerships. As an example, Judson's West

Coast stockist Bill Correy was also a

representative for Pepco Superchargers and a regular feature contributor to "Road

& Track" magazine. I would expect he had no small part in

getting the Judson reviewed in the September '57 issue. The VW Kit at this

time retailed for $149.50. The fact

that Judson were selling their supercharger kits for the VW through VW of

America's official dealership network is a little surprising, given VWs

open hostility to any tinkering with their flat 4 engine.

It is also surprising that it wasn't until 1960, that VWoA

decided to put their foot down; threatening any official VW dealership with

the loss of their franchise if they continued selling accessories not

sanctioned as official VW accessories. VWoA

also reminded dealerships, that fitting a Judson Supercharger to a VW would

immediately invalidate their warranty. The

closing of these sales outlets led to the production of a Judson

"Personal Memo" mail-shot to prospective owners who had already

asked for product details. In it Charles Judson explains why local VW dealers

were no longer stocking the Judson Supercharger. More importantly to the

buyer, the memo announced the company was passing on the dealer discount,

reducing the price of the VW kit from $144.00 to a very attractive, $100.00

when buying a supercharger direct from Judson's Conshohocken workshop.

|

|

1964-1976 |

|

We are fortunate to have, in the writing of this

"history" the assistance of Rocco Antonelli to paint a picture of

the Judson Research & Mfg Co. during these last

12 years of supercharger production. Rocco joined the company in 1964 as an 18

year old after what Rocco recalls as rather an intimidating interview.

Both Haddon and Charles Judson conducted the "grilling," putting

Rocco through his paces to see if he would stand his ground. "Can

you hold a thousandth," probed Haddon brusquely. "If

your machines are up to it, I can hold a tenth of that," was Rocco's reply. Haddon

turned to Charles and said, "Let's see if he's as good as he says he

is." "Boy...you

start on Monday." Rocco was

to be part of a close-knit team in a precision engineering environment...if

you couldn't "cut it" you would be out. William Haddon Judson was a

"hands on" owner who ran a tight ship. Rocco slotted right into the

operation, which saw him gain the trust of the demanding owner to such an

extent that he found himself in charge of the Supercharger Division inside of

two years! It was a relationship of mutual respect. The two

Judson brothers were the driving force of the Judson Research & Mfg.

Co. but almost direct opposites in character: William Haddon Judson was the innovator and inventor, the very reason the company was a success. He had a tough exterior, didn't suffer fools gladly and would let you know exactly what he thought. Not for him the confines of the office, "Had" set his personal lathe at the head of the machine-shop and got his hands dirty along with the rest of his team. You would rarely see Haddon out of his white lab-coat. Haddon drove a silver Mercedes 190 with beautiful red leather upholstery, it was his pride and joy...supercharged of course. Although Haddon never took the academic route to engineering proficiency he was made an honorary member of the "Society of Automobile Engineers" (SAE). He was proud to display the citation on a plaque in the hallway that linked the offices to the workshop. Charles Avery Judson was the administrator and PR man. Charles spent his day in the office, dealt with finances, advertising and customer relations. Charles was a very elegant man, always dressed immaculately in tailored suits and bow-tie. Although it was Haddon who was the engineer, it was Charles who drove the fast cars...most of them supercharged too.

|

|

Staffing. |

|

One might

consider a company that produced a variety of original engineering and

electronic products from its facility in Conshohocken to be quite a large

concern, with a staff of between 30 and 50 people...not so. The Judson

Research & Mfg. Co was at no stage manned by more than 10 members of

staff. Having said that, many of that number would have the capability to

"multi-task" across engineering and electronic projects and, as the

company name suggests, research into new products. We'll let Rocco recount the main Judson staffing during the

time he was recruited... W. Haddon Judson had three children; two sons, W. Haddon Judson jnr and Gregory Judson and a daughter, Patricia. Although the two sons worked with their father, Haddon jnr. spent a large part of the 1960s in the US Navy and sadly Greg died suddenly in his early 20s. The the early death of Greg was a tragic blow to the family and understandably hit his father badly for quite some time afterwards. Charles A Judson had one son, Christopher. The two

Judson brothers insisted on a tight discipline in the workplace...no talking,

except at break time..."and put the cigarette down, I'm paying you

for two hands, not one!" However it didn't

stop Haddon from flipping me with the occasional cigar as he returned from

his lunch break. I kept it to smoke in my own time of course. Neven Tyson was a supervisor who ran a turret lathe which was centrally located so he could see the whole shop. "Nev" was a war hero and I can't say enough of how nice a man he was. He was one of the few survivors of the WWII Bouganville campaign, in the South Pacific. His recollections of that campaign were the stuff of nightmares; it forever gave him a deep respect for life, and his fellow workers. I learned valuable life lessons, as well as gained a friend in Nev. Stanley Pruskowski, shop foreman, who loved to work overtime and did a dance he called "The Overtime Samba" whenever Saturday working was posted. Rich Baker, who ran the electronics department and the owner of a "nasty" white Corvair. Rich and I worked that car over until it screamed! And of course myself, Rocco Antonelli. That pretty much rounds up the people who

worked there for any period of time. There were

others who came and went in the meantime but just a core workforce of six

people made up Judson Research & Mfg. Co. for a large part of my

time at the Conshohocken PA. facility. Editorial note: Rocco was considered by Haddon Judson to be the

best lathe worker he had ever worked with and when the company closed the

supercharger operation in 1976, gave Rocco glowing job references, and

introductions which helped further his later career.

|

|

The Judson Workshops. |

|

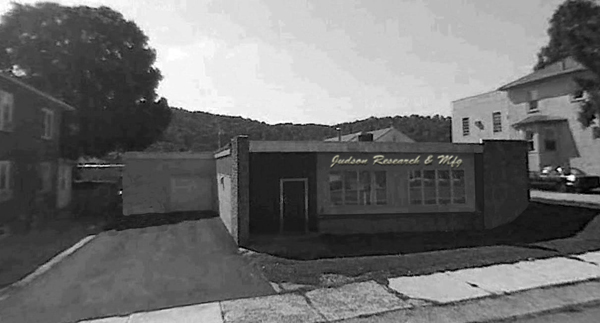

At the time of writing no period pictures of the Judson

facility at Hector Street, Conshohocken has been found but as the workshops

still stand, I have adapted a recent "Google Earth" picture

with Rocco's assistance, to show the workshop and offices as it would have

appeared in the mid 1960s. In the mid 1950s the supercharger operation was relocated to 541 E. Hector Street, Conshohocken (pictured right) and it was from here most of the Judson Superchargers were made and despatched. Later, the modern day Judson Company was restarted by W. Haddon Judson Snr. and W. Haddon Judson Jnr. in an old tubing mill on Washington Ave. in Conshohocken. The same tubing mill that was started by W. Haddon Judson Snr's father, originally making .30 and .50 calibre machine gun barrels for the military during World War Two. |

|

So what was it like inside the E. Hector Street facility? Rocco

has kindly drawn a pen-picture of the set-up and lay-out of the workshop. |

|

Rocco

continues: The

Judson building from the front was a single story, twelve-car garage, an

imitation stone fascia with a large picture window, a 2 cars deep single lane

driveway nestled between two old private homes. From the back, a large garage

with one shipping dock, one receiving dock and one employee entrance door.

Although a nice looking place and spotless on the

inside, you would never believe any type of machining ever took place in this

shop. It looked more like a show place for old machinery. Now to

the shop lay-out, I only hope I can describe the shop well enough that you

can visualize it. It was, as machine shops go, Outstanding! "Had"

insisted on sparkling clean machinery. We had to brush and wipe down, then

blow down every machine used, then run fresh lithium grease through the

bearings, until the grease was clean. Repeat in the morning if machine was to

be used. In 10 years or so, we had to replace one bearing in one drill press! The

back of the building had 3 doors, two over head,

one small centre door for employees entry. Castings

were made at the Emmaus Foundry Co, in Emmaus, Pa. (this company was also

owned by W. Haddon Judson). Castings were delivered by truck and stacked on

the concrete floor to help season them (a debatable issue). As you

walked in the employee entrance, on the right side of the shop, in an

assembly line order: STEP

2 STEP

3 STEP

4 STEP

5

STEP

6 STEP

7 In

about 30 to 40 minutes, a finished housing. On the right

hand side of the shop were two milling and slotting machines to slot

the rotors, shaft and vane slots. On the left side, two beautifully

made milling machines for cutting aluminum

manifolds, both vintage; one German made, one Italian made. I would have

liked to have them, I mean they were beautiful. Next

in line a row of single head drills and multi-head tapping machines. Next

"Nev's" turret lathe, then two engine

lathes, then "Had's" magnificent British

made white enamel collet chuck. I wish that was mine also, then the band saw.

Next to that, the Infra-red laboratory. Now

the far left aisle of the shop. First the table disk

sander, a large paint booth, a degreasing tank, a Sunnen10 honing machine,

another degreaser tank. Next, the welding station and finally Had's work bench. Nev did most of the rotor work, as well as the end plates, I

did the rest including balancing on the Gishault.

Rotors were tuned and faced off by Nev as well as

slotting and threading. Most of this was done on Nevs

turret lathe, slotting was done on a modified milling /grinding indexing

table; we shared this job. As sales dropped off later in the early '70s, Nev and I took over the entire procedure. Vanes were hand

cut with a hand fed router. A radius and a slotting head (

made by Haddon ) were all that was needed. Close and careful

inspection was was the

rule. Haddon

designed, built and organized the steps and the machinery. Everything worked

just right ! |